CFD Modeling

Computational Fluid Dynamic (CFD) provides a greater insight into the mechanisms affecting the combustion of fuels.

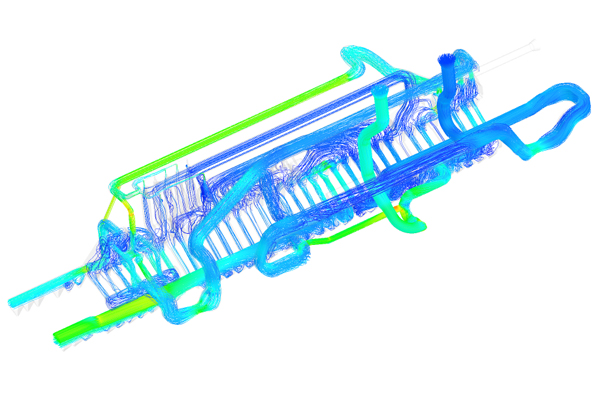

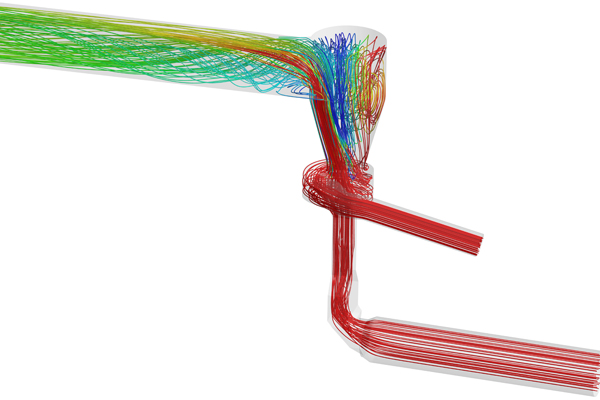

It offers the ability to examine the secondary air aerodynamics, temperature profiles, concentrations of combustion products as well as tracking the chemical reactions of heated solid particles. In addition to kiln combustion it is particularly useful for two phase flow such as that found in calciner vessels where air, fuel and solids interact. MEEMCO CFD team has years of experience in modelling and understands the rigors of data collection necessary for accurate modelling and how to translate the results to give meaningful outcomes. Suits rotary kilns and coolers, calciners vessels, furnaces, cement, lime, pulp and paper and minerals processing.

Features

-

Temperature profiles and heat flux inside the process are presented graphically

-

Graphic representation of the flames interaction with the secondary air stream

-

Concentrations of species can be followed inside the process, ie O2, CO, CO2, NOx, CaCO3 etc

-

Report with images generated and includes technical drawings of the suggested modifications for direct implementation of the solution

-

Improvement actions can be planned and installed during a scheduled shutdown, minimizing downtime and risk